A Fine Line for Ferris

In December 2018, Windemuller received an emergency call from Ferris State University. Contractors for Ferris had been doing some steam line repairs on the property and had come across three 4-inch conduits above the lines. The university, believing the conduit to be abandoned/no long in use, gave the crews the go-ahead to cut through it to achieve better access to the steam lines. Only after the conduits were cut did Ferris discover that one of the lines was a 900-pair copper phone cable responsible for supplying lines to several campus buildings. Ferris then contacted Windemuller and asked for our help restoring the phone lines before students returned from the winter holiday break.

The Challenge

The urgent nature of the project did not provide enough time for Windemuller to put in a permanent fix before students came back to school. Instead, we needed to come up with a temporary solution that could feasibly last for the remainder of the school year. Once that fix was in place, we had to go back to the drawing board to figure out a permanent solution—and hopefully one that would get our crews away from active steam lines. The result was a job that was essentially two separate projects in one.

The Solution

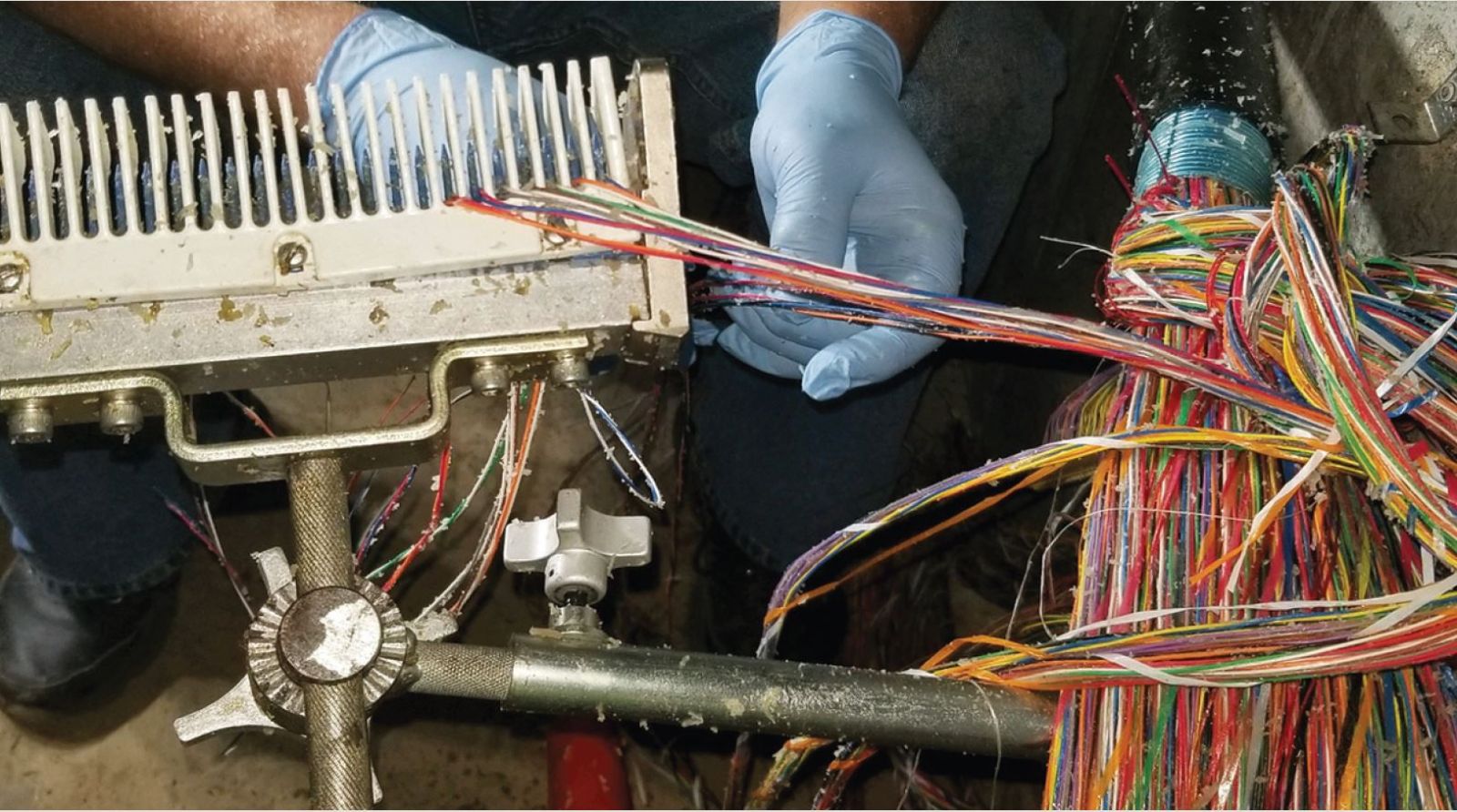

In the week between Christmas and New Year’s, Windemuller worked to create temporary splices in the existing trench where the conduit had been cut. This repair involved a combination of 100-pair and 200-pair cable to bridge the gap in the 900-pair cable. Our Techs worked for five days to get the cable connected, taking care to track the binder color closely. With the phone lines to Ferris buildings restored, we started to form a plan to replace the entire damaged section of 900-pair cable. We wanted to avoid a situation where our team would be crawling through active steam lines, which meant rerouting the damaged conduit to a different spot. By the time summer arrived and most Ferris students were off campus, we were ready to return to the site of the conduit, re-excavate the area (with the help of Morningstar Excavating), redirect the conduits, pull in new cable, and splice the new 900-pair cable to the existing cable in two locations. This plan not only provided the permanent fix that Ferris needed, but was also so thoroughly planned out that we were able to keep the outage to just three days.