All Pumped Up In Grand Rapids

The Lake Michigan Filtration Plant in West Olive, Michigan is owned by the City of Grand Rapids and is responsible for pulling in water from Lake Michigan, treating it, and pumping it all the way to the Grand Rapids area, approximately 30 miles away.

Overview

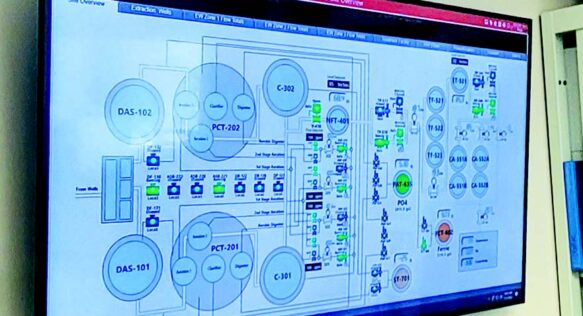

The Lake Michigan Filtration Plant provides all the municipal water used by the City of Grand Rapids and surrounding communities and suburbs. The plant is able to deliver treated lake water to the city thanks to the presence of powerful HLPs, four of which were due for replacement in 2018. Windemuller installed new variable-frequency drives and motor control centers (MCCs) for the filtration plant’s new HLP 5&6. Previously, the pumps were fed by 2,300V switchgear, which required the use of a step-down transformer to convert incoming power from 4,160 volts to 2,300 volts. The new installation removes this potential point of failure by installing redundant new 4160V MCC’s with a Main-Tie-Main, a 4160V Variable Speed Drive, and 4160V motors. This upgrade allowed for the complete removal of the old step-down transformers and 2300V MCC.

The Challenge

The first major challenge was incorporating equipment from two different manufacturers: Rockwell Automation’s variable-frequency drives and Eaton Corporation’s MCCs. Getting the equipment to work together seamlessly required careful layout and planning.

The second challenge involved considerable delays in the arrival of new pumps. When the pumps did come in, they were faulty. We could not proceed with our piece of the project until HLP 5&6 were in place, which meant extensive coordination with the city to maintain adequate water supply through high demand seasons.

The Solution

We partnered with folks from both Rockwell Automation and Eaton Corporation to help commission and integrate their equipment while maintaining the customer’s valuable warranty protection on their investment. These partner’s assistance was invaluable.

As for the delays, our piece of the project ended up extending out about six months later than we anticipated. During this extension, Windemuller was able to land a second project at the Lake Michigan Filtration Plant. Rather than bringing in a completely new crew to handle the second job, we were able to coordinate our manpower from one side of the plant (where we were waiting to move forward on the HLP project) to the other side (where the work involved pre-treatment upgrades for the plant). Being nimble and able to work on the second project while the first one was delayed enabled us to provide additional value to the customer and kept our crew working efficiently until the new pumps arrived.