Smeltzer Orchard Automation

• Developed new automated controls system

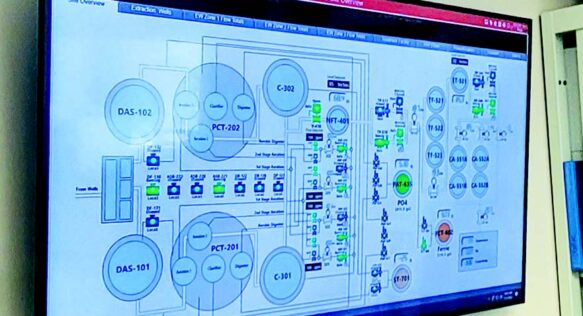

• Installed advanced control panel with updated PLC and HMI

• Aggressive timeframe to minimize system downtime

Overview

Smeltzer Orchard, a large-scale fruit processor and distributor based in northern Michigan, partnered with Windemuller to complete a multi-phase project to improve their automation system. After completing phase one of the project, our automation team quickly got to work on phase two. Smeltzer’s existing control system was out of date and needed an upgrade, and they needed it done quickly. Eliminating downtime and completing the work within the given timeframe was extremely important to the customer. The Windemuller team worked overtime and through the weekend to complete the installation in less than a week, ensuring the plant could quickly resume production.

The customer’s number one priority was to update their controls system to a fully automated system for product consistency. The existing system operated manually with push buttons and switches – and was extremely unreliable. Our team removed the previous control panel and installed a new panel with updated PLC and HMI for controls. The customer was rewarded with peace of mind, increased reliability and an easier way to troubleshoot. Our team completed this project on time and the customer was back to processing quickly with the new automated control system.