Better Communications for Chemistry

Dow Chemical was seeking an extensive communications upgrade for its Midland facilities. The project went to Commdex Consulting LLC, via Motorola and Commdex brought Windemuller onboard to update the two-way radio systems that Dow was using in all its plants in the Midland area. The broader project involved upgrading from an analog communication system to a digital system—a process that included installing a brand-new tower and transferring over communication services.

The core focus of the project were seven buildings that Dow had designated as “high-impact areas.” Dow wanted 95 percent coverage in each of these buildings for the two-way radio systems Windemuller had been contracted to install.

The Challenge

Commdex provided the design and materials for the installation, but Windemuller needed to tweak the design for parts of each facility that were unable to accommodate the system as planned. Some parts of the design required demanded field adjustments due to limited access. Given Dow’s status as a chemical company, there were several parts of the facility that were high risk and classified whether it be corrosive, flammable or explosive and this had to be considered in the overall plan.

Regarding safety policies, Dow Chemical transitioned mid-way through the project to a new standard for fall protection. Where Dow’s old policy had allowed for work at a height of six feet without fall protection, the new policy reduced the height to four feet. The change left Windemuller to find a smart way to meet Dow’s standard and keep our workers safe without sacrificing productivity.

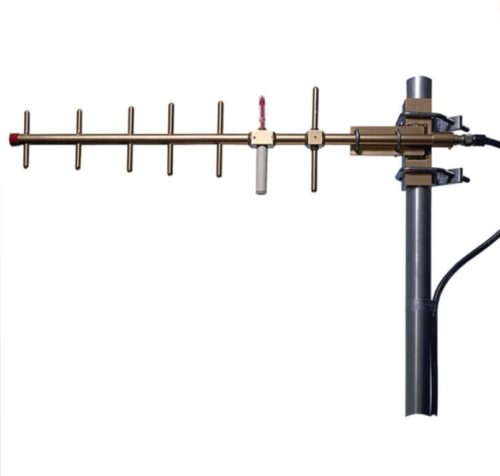

Another challenge was positioning the antennas for the two-way radio system on the roofs of each building. Planning the penetrations from each facility to the roof was a hurdle, as we needed to feed coaxial cable from the antenna into the building—but couldn’t risk compromising the roof for such a sensitive environment.

Finally, the project timeline proved to be a challenge. We had a three-and-a-half-month window to get the radios installed and online—a schedule complicated by the varying schedules at the Dow facilities. In some cases this meant working on weekends and evenings.

The Solution

Windemuller worked closely with Commdex and Dow personnel to find alternate paths for installation that would keep us as close as possible to the original project design. In some cases, we needed to adapt the plan to suit the safety protocols of the facility. In other cases, we were able to continue on as planned, but had to follow specific protocols both during installation to minimize safety concerns and after completion for safe, accessible maintenance.

To adhere to the new fall protection protocols, we pivoted mid-way through the project from using ladders to utilizing lifts and scaffolding. We brought in Niles Plant Services to provide scaffolding for parts of the facility where we could not use lifts.

We also ended up calling in backup to help ensure the integrity of the roof during and after antenna installations. Bri-Car Roofing was the Dow-preferred roofing contractor and did a terrific job bringing the roofs back to near-original condition.

Finally, to accommodate scheduling, our crew members were superstars and stayed flexible in their willingness to work after hours and into the evenings.