Control System Upgrades

Overview

The Ott/Story/Cordova Chemical Co. site in Muskegon, a former organic chemical production facility, faced a major challenge with its outdated control system. This system urgently needed extensive repairs and updates, especially after a recent failure that brought the entire plant to a standstill. The existing SCADA system was no longer effective, requiring manual checks by operators for equipment status, tank levels, and basic plant operations.

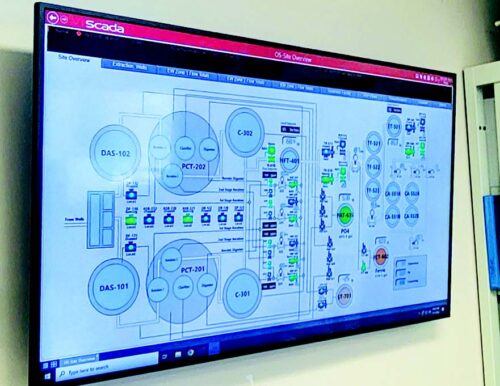

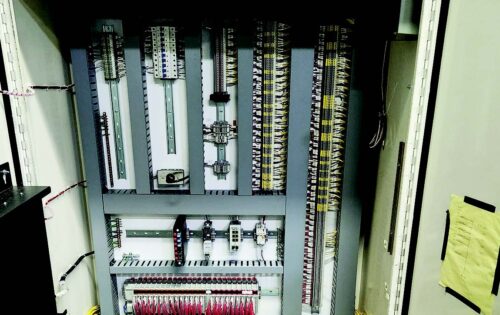

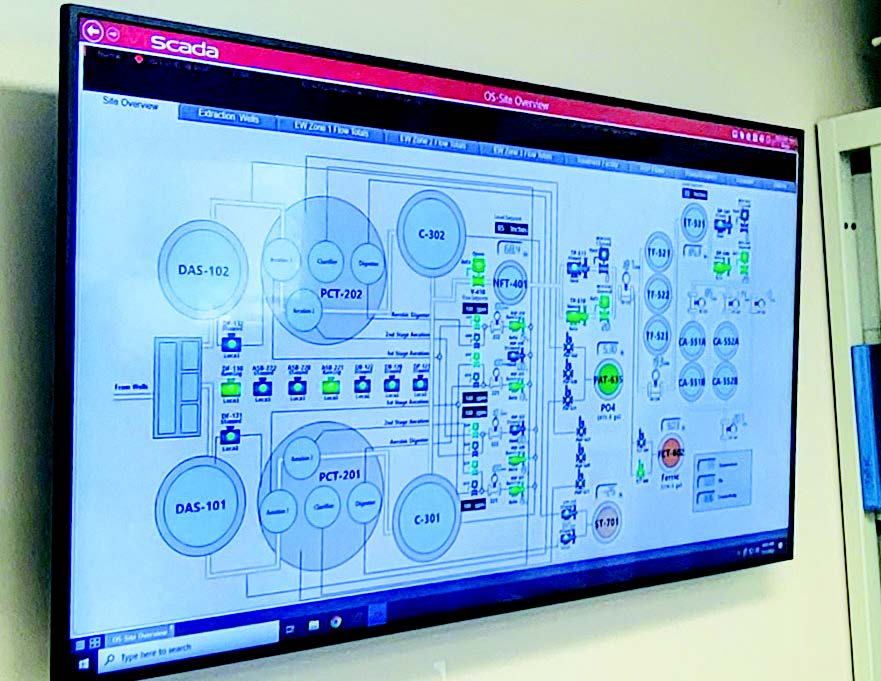

Understanding the urgency of modernization, Windemuller worked closely with the plant team to tackle these issues. Our first step was designing and building five new back panels to accommodate the new control systems for both the plant and remote well stations. We then carried out a systematic on-site installation, replacing the old panels with the newly constructed ones. Our team installed a new VTSCADA system, complete with graphics for screen displays, motor controls, levels, trending, and alarming. This not only provided local system controls but also enabled remote monitoring and control.

The Windemuller panel build team played a crucial role, in designing and facilitating the exchange process. Collaboration extended to our electrical and communications teams to ensure a smooth transition to the updated control infrastructure.

As the project unfolded, Windemuller’s commitment to excellence led to additional improvements. We issued several change orders to implement enhancements, such as flow controls and upgrades to Motor Control Centers (MCC) Variable Frequency Drives (VFD). This

comprehensive approach not only resolved immediate issues but also boosted the overall efficiency and capabilities of the plant.