Power to the Soybean

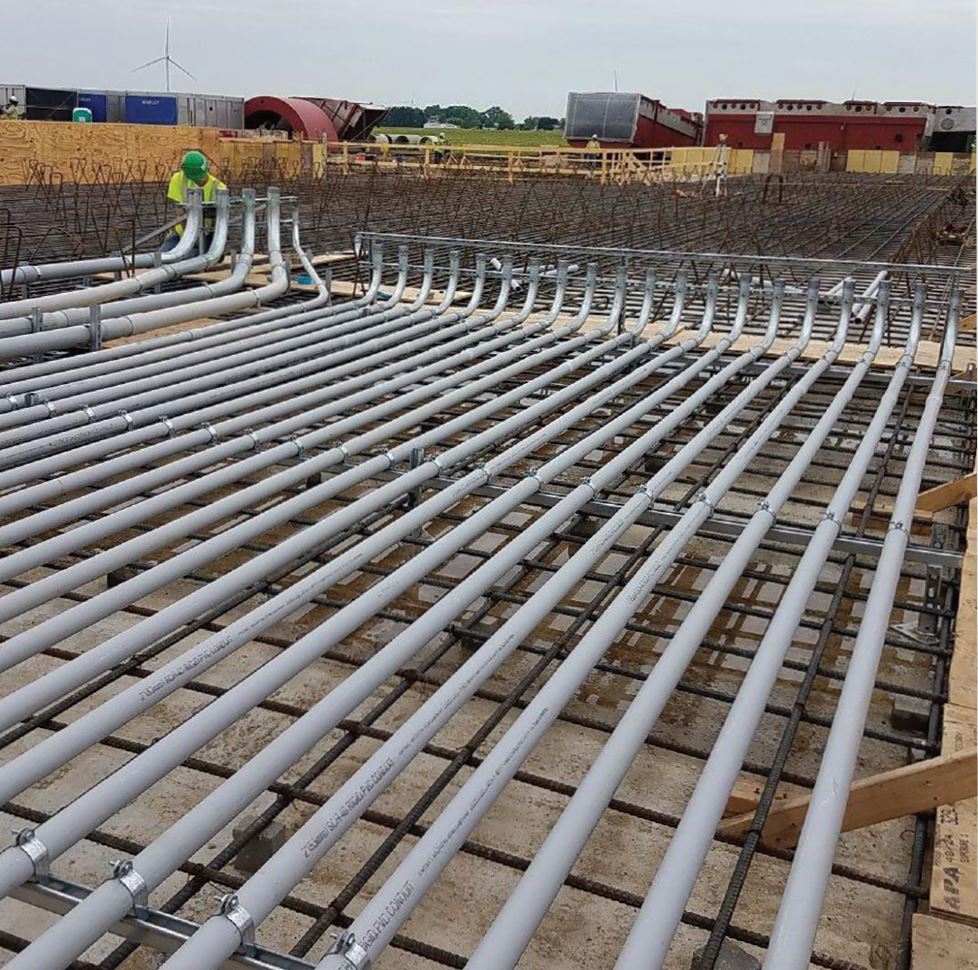

For over 20 years, Zeeland Farm Services, Inc. has been the largest soybean processor in the state of Michigan. ZFS Ithaca, an affiliate of Zeeland Farm Services, will soon take over that mantle. In order for the changing of the guard to happen, though, ZFS Ithaca needed to build a brand-new facility from the ground up. The project involved redeveloping the site of an existing ethanol plant brownfield into a facility capable of 40 million bushel-per-year soybean processing. ZFS Ithaca projects that the facility will singlehandedly quadruple Michigan’s soybean processing capacity. Windemuller played a key role in the project, installing underground conduit raceways and other underground utilities to deliver the necessary electricity to the site.

The Challenge

Most of the challenges on this were related to the sheer size of the project itself. Windemuller was working as part of a team that included many other contractors, on a job that involved multiple priorities and moving parts. This situation led to a few instances where we adjusted our plans on the fly to respond to unexpected worksite challenges.

First, the initial project plan had been for Fagen, Inc., the general contractor, to handle excavation work ahead of time. That preparation work would have allowed our technicians could go right into the trench and start working on underground conduit installations on day one. However, due to short-staffing and other project demands, Fagen ended up shifting that responsibility to us instead. Since we are not an excavation contractor, this change meant we adjusted our plans significantly.

Second, synchronizing schedules across all of the different contractors working on this project was incredibly challenging. In some cases, other contractors ran behind schedule and we had to delay our timeline accordingly. Other contractors, meanwhile, were working very quickly. There were some days where one team would be erecting steel structures for new buildings at the same time that Windemuller finishing work in the ground next to those buildings. These scheduling clashes caused a few problems with worksite coordination.

Finally, the project fell right in the midst of a very wet year, which meant there was almost always water in our trench when we got to work in the morning.

The Solution

Our ability to be resourceful and flexible was arguably Windemuller’s greatest asset on this project.

When plans fell through for Fagen to handle excavation work, we pivoted quickly, working to get our hands on the right equipment, leverage our Outdoor Utility team’s skills and expertise, and partner with Matt’s Underground (an excavator) to expedite as needed. Our rapid responsiveness allowed us to handle much of the earthwork for the project, and kept enough open trench for our teams to keep working on underground utilities.

When schedule clashes threatened to bring the project to a grinding halt, we communicated with Fagen about the issue to ensure we were able to work where we needed to work. This coordination with the wonderful general contractor and other teams helped us change our plans when delays in certain parts of the project might have otherwise set us back.

Finally, when the less-than-ideal weather conditions put up roadblocks, we did what we could to plow through them. Our crews got used to pumping water out of the trench wherever we were working. And when winter came around and problems with wet, muddy soils turned into problems with frozen ground, our crews got used to thawing the ground so they could dig.

Our flexibility even applied to changes in the project plan itself. When the client approached us late in the game about installing a medium-voltage feed from the substation to the distribution switchboard, we dove right in. The installation—which encompasses 22,000 feet of 500 MCM, 15kV cable—will be a crucial electrical component for this new game-changing facility.

In the long run, the new ZFS Ithaca plant stands to change the face of soybean processing and agriculture in general in the state of Michigan. Windemuller is proud to have played a role in building that future.