Wired Up For Production

• Installed cable trays, conduit, and electrical control panels for new insulation equipment

• Strategized best route for cables to run between two locations

• Altered insulation machinery to continue production

Overview

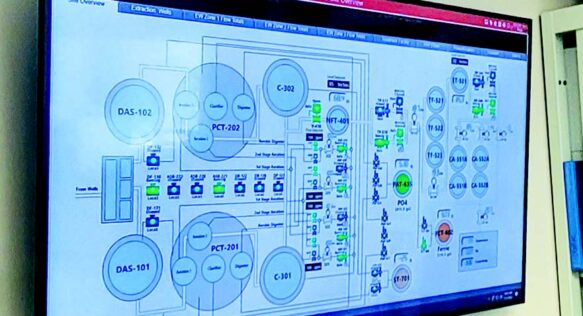

Nu-Wool Co., Inc. is an environmentally friendly cellulose insulation manufacturer located in Jenison, Michigan, which was ready to upgrade their manufacturing facility with all new production equipment. Windemuller was tasked with wiring the production to get their new equipment up and running. The job included the installation of new cable trays, conduit, and electrical control panels. Additionally, they had to map out the most effective route to run the cables between two separate locations. There were many moving parts involved in this job and the team had to be extra intentional and strategic with their actions.

Over the last few years, most companies have experienced supply chain challenges, and this job was no exception. This project experienced numerous delays, including the compressor, an integral part of this project, which was stuck in Italy for an extended amount of time. To combat the issue, we worked closely with Nu-Wool and devised a plan to get the production floor up and running as soon as possible. Windemuller rearranged specific parts to the end of the insulation oven, which allowed the customer to begin some production while we waited for the compressor to arrive. Eventually, all parts arrived, and production is now running normally, with ease. This project required strong communication while we worked alongside the Nu-Wool team. Despite the ongoing supply-chain issues, Windemuller was able to solve a complex problem and complete the job.